Seaweed in Ireland has a longstanding tradition and is cemented in Irish folklore but its use has been lost in recent years. Recognising the potential of seaweed, The Seaweed Company used EU funds to develop a seaweed farm and Ireland’s first dedicated seaweed processing facility.

Farming seaweed in Mulroy Bay

Mulroy Bay in Donegal is a sheltered sea loch meaning it is perfect for the development of aquaculture. Alongside seaweed farming, the bay is home to several mussel and salmon aquaculture sites, while local fishers also hand-dive for scallops and native oysters. The bay has 13 naturally occurring seaweed species including Alaria (often referred to as Atlantic Wakame). Alaria, a species of kelp native to cold, temperate climates, has been studied and identified as a good candidate for seaweed aquaculture.

General Manager of the processing facility, Lorraine Gallagher, has a longstanding affiliation with Mulroy Bay. Her family has a shellfish business in the area which has produced scallops for over 30 years. Using this local know-how, as well as training as a phycologist, Lorraine teamed up with the Seaweed Company to diversify their site on the bay and to open a seaweed processing facility – a first in Ireland.

As stated by Lorraine Gallagher, General Manager of The Seaweed Company: “Mulroy Bay is perfect for the production of seaweed. We have very cold waters in which species such as Alaria thrive. The bay is also very sheltered and often referred to as ‘fjord-like,’ long and winding, and protected from the open waters, which is an ideal setting for aquaculture."

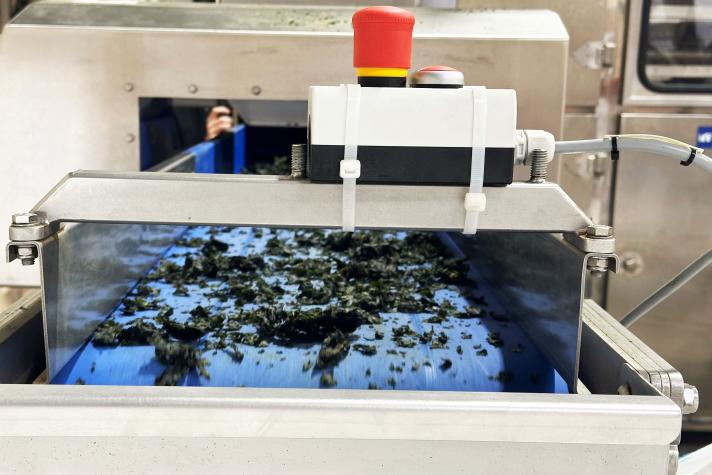

Processing seaweed

Once harvested and removed from the water, seaweed deteriorates quickly if not processed. At The Seaweed Company’s processing site in Donegal, the seaweed is first cleaned and shredded before going through a fast-drying machine. From leaving the harvesting site, in less than three hours, the seaweed can be processed, dried, and bagged, ready for shipping.

Lorriane Gallagher underlines the importance of EU support: “Without EU-funding, this project would not have been possible. The funding has allowed us to scale-up our production as well as develop our new processing facility which allows us to dry the seaweed quickly so it can be transported and used in food production.”

Environmental impacts and uses

The primary use for the processed seaweed is SeaMeat®, a meat substitute which is added to products such as beef burgers. Butchers and meat producers replace 25% of the meat in products such as beef burgers with the seaweed which has several benefits including acting as a natural seasoning and texture to the meat.

The addition of seaweed can also increase the shelf life of meat products by up to one day, thus reducing food waste. Adding seaweed furthermore reduces the CO2 emissions associated with the meat products, making them more environmentally friendly.

Future plans for the seaweed farm and the processing facility include the development of new products for varying sectors including horticulture and pharmaceuticals. Other food products are also on The Seaweed Company’s research and development agenda who already produce novel products using other seaweeds such as chocolate and a range of soft drinks.

Like father, like daughter

Lorraine’s story exemplifies the need for generational renewal in the fisheries and aquaculture sectors. As a second-generation aquaculture producer, she has diversified the family business into an exciting and growing sector. Lorraine and her father, Jerry Gallagher, are looking to further grow their aquaculture site in Mulroy Bay – they plan to experiment with different seaweed species found in the bay and new methods of production.

“Through my father, we have the best local expert available to us. He is a custodian of the bay, and his knowledge is irreplaceable as we grow the Seaweed Company business here in Ireland.” – Lorriane Gallagher, General Manager of The Seaweed Company

More information

Video on the project (long version)

Video on the project (short version)

Details

- Publication date

- 24 September 2024

- Author

- Directorate-General for Maritime Affairs and Fisheries